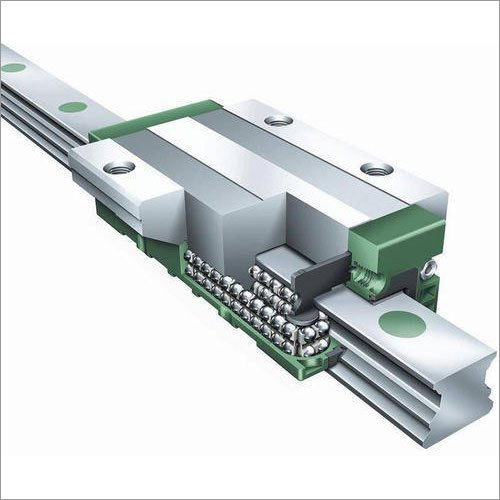

Linear Guideways

Product Details:

- Product Type box

- Length 100 - 4000 Millimeter (mm)

- Material Stainless Steel

- Click to View more

Linear Guideways Price And Quantity

- 10-1000 Piece

Linear Guideways Specification

- 100 - 4000 Millimeter (mm)

- box

- Stainless Steel

Linear Guideways Trade Information

- Cash on Delivery (COD) Cash Advance (CA)

- 1000-2000 Piece Per Month

- 10 Days

Product Description

Backed by a group of enormously skilled professionals, our firm is manufacturing, supplying, exporting, trading and importing an exclusive range of the Linear Guideways. The offered products are manufactured by using the superior quality stainless steel components and sophisticated tools & techniques as per the market standards. By re-circulating rolling elements, it provides linear motion between a bearing block and a profiled rail. We ensure they are able to take loads in all directions and have various advantages such as high positional accuracy, interchange ability, installation, easy Lubrication, long life with high motion accuracy, etc. Apart from this, the range of the Linear Guideways in various specifications and at market leading prices.

| Length | 100 mm - 4000 mm |

| Material | Stainless Steel |

| Hardness | 50 - 60 HRC |

| Diameter | 10 mm - 65 mm |

| Packaging Type | Box |

To meet the diverse needs of our valued clients, we are providing a high-quality selection of Linear Guideways

FAQs : Linear Guideways

What are the types of guideways?

Types of guideways include: recirculating ball type, rolling type, and linear roller type.

What are the advantages of linear guideways?

Advantages of linear guideways include improved accuracy, reduced friction and wear, increased load capacity, and longer life compared to traditional sliding guides.

What materials are used for guideways?

Common materials used for guideways include steel, stainless steel, and aluminum. Some high-precision systems may also use ceramics or engineered plastics for their low friction and high wear resistance properties.

What types of applications are best suited for linear guideways?

Linear guideways are ideal for applications that require precise positioning and repeatability, such as machine tools, robotics, and automated assembly lines. They are also used in medical equipment, semiconductor manufacturing, and other industrial applications.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free